General Operational Overview

The Tie-FenLock 400 system is presented on the Visual Display Unit (VDU) in front of the user. Any equipment controllable by the user can be clicked with the mouse using the left-click for standard

operation and a right-click for failure/administrator roles.

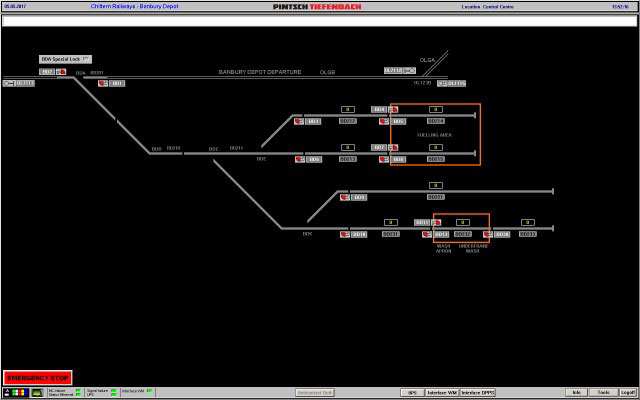

As an additional feature, the software can be configured to show a car count, which is achieved by taking the axle count and dividing by the number of axles per car/carriage/coach (typically 4). This is visible in Figure 1, circled in blue, which becomes of benefit when permissive working is specified as it allows the operator to see the remaining stabling capacity.

Each interlocking request also features a yes/no option to complete the operation. This is to prevent accidental requests. Fault messages and degraded mode operations provide an additional pop-up image and window and each must be acknowledged before the system executes a new request.

Figure 1 – VDU with route set, track occupation and car count (blue circle)

Figure 1 – VDU with route set, track occupation and car count (blue circle)

Example of Operation

The most commonly used function on a Tie-FenLock 400 system is setting a route which is performed by 5 mouse clicks:

Start |

|

|

|

Finish |

|

Click on the signal at the start of the desired route,

|

Select “START” from the drop-down list that appears,

|

Click on the signal at the end of the desired route,

|

Select “DEST” from the dropdown list that appears,

A message appears “Set route A to B?” with buttons YES and NO. The YES/NO are blanked out for 3 seconds before becoming available to mitigate erroneous setting. |

Click YES

If the route conditions are satisfactory, the route sets and a message “Route A to B set” appears and the VDU reflects lineside equipment states. If the route conditions are not satisfactory (e.g. points locked in the incorrect lie), the route does not set and a message “Route A to B setting cancelled – Points C locked reverse”. |

Other equipment can be indicated and controlled by status indicators which are pop up boxes showing green for on and red for off, examples including:

Background Operations

The system automatically records each action taken on the system into an activity log. Each log entry includes the date, time, location and operator. Some items may include (non-exhaustive):

The log can be downloaded from the interlocking or viewed on the VDU and is generally an aid to fault finding exercises.

Multiple VDUs

There is flexibility in having multiple operator’s desks (i.e. two separate VDUs in separate locations). The same connection applies and is via a secure and reliable network (ethernet) cable. The multiple VDU setup is configured in such a way that it is possible for only one of the terminals to be designated the master at any one time. A secure function is built into the user interface to enable the hand-over of control and uses a multiple action command to permit the currently active master to designate another terminal as the new master.

Forward House

High Street

Henley in Arden

B95 5AA

T: 03300 580180

T: 01926 358428

Click here to subscribe to updates from Fenix Rail Systems